In the metalworking industry, each additional production step incurs costs: part handling, transport between workshops, extended lead times, and increased inventory.

At KUCHLY, we offer a simple and efficient alternative: performing stamping and tapping in a single operation, directly in the same tooling.

Since 1956, our expertise in stamping and flow tapping has enabled us to integrate these two processes into a 2-in-1 process that is faster, more economical, and more reliable.

Discover how this technique can transform your production chain.

The principle of integrated tapping in stamping

Stamping with integrated tapping consists of forming and threading the metal part in a single press pass.

Our design office develops progressive dies capable of combining several successive operations: cutting, stamping, then tapping directly integrated into the same tooling.

Unlike conventional chip-removal tapping, flow tapping deforms the material instead of cutting it. Threads are formed by compression in a calibrated hole, without chip production.

This process improves the mechanical strength of the thread thanks to the phenomenon of strain hardening, particularly useful for parts subjected to repeated stress or vibrations.

The choice of metal is therefore essential: certain high-strength low-alloy (HSLA) steels or some stainless steels do not tolerate cold deformation well. KUCHLY advises you on the best compromise between strength and flowability, to ensure reliable and durable tapping.

KUCHLY masters this technique up to M12 tapping in sheet metal only 1.5 mm thick, a level of precision made possible by over 70 years of experience in metalworking.

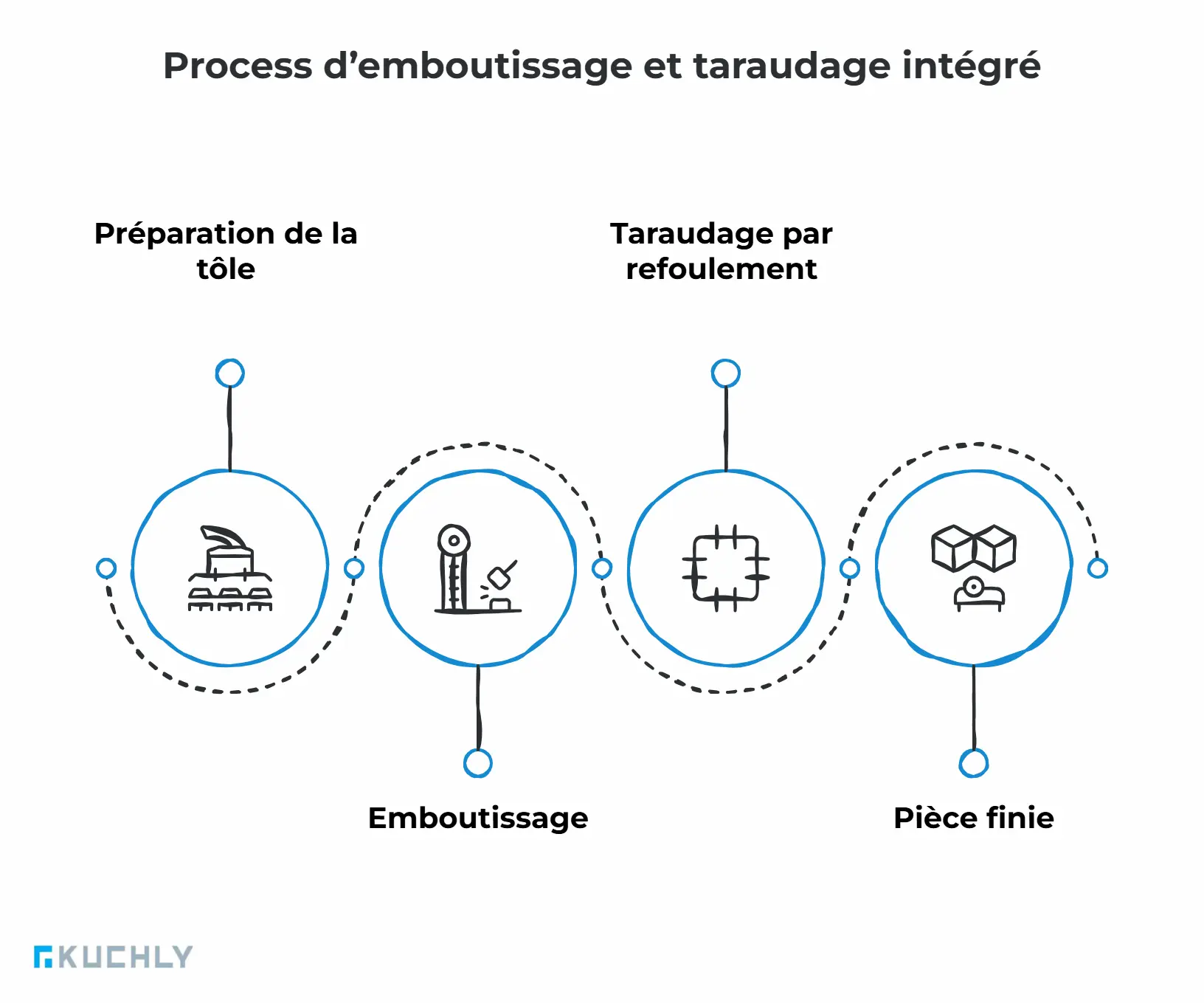

How an integrated stamping and tapping process unfolds

- Sheet metal preparation: the metal strip is positioned on the press from a coil.

- Stamping: the sheet metal is shaped by the punch and die to create the desired volume.

- Flow tapping: the tap deforms the material and creates the thread without chip removal.

- Finished part: the part emerges directly stamped and tapped, ready for assembly or delivery.

The advantages of this technique for your production

A single operation, a single point of contact

Integrating tapping into the stamping tooling allows for the elimination of transfers between workshops.

You no longer manage two service providers or two distinct processes: a single tooling, a single supplier, simplified traceability.

By performing everything in-house, KUCHLY guarantees perfect coaxiality between stamping and tapping. The risk of non-compliance is significantly reduced, and administrative monitoring is streamlined.

Costs and lead times halved

The absence of transport and intermediate handling significantly reduces lead times. Where a traditional process requires 4 to 6 weeks, our integrated solution often allows for delivery in 2 to 3 weeks.

Regarding costs, savings come from:

- the elimination of transport and rework,

- a single tooling amortization,

- the reduction of buffer stocks,

- and improved agility in production planning.

This approach becomes particularly interesting for medium and large series, where the investment in combined tooling is quickly amortized.

Superior mechanical quality

Flow tapping improves thread strength through cold metal deformation. The resulting threads exhibit better tightening resistance, withstand screwing-unscrewing cycles more effectively, and tolerate vibrating environments.

Another major advantage: no chips are generated. The process is therefore cleaner, safer, and complies with the requirements of sectors where part cleanliness is critical, such as medical or food processing.

Concrete and adaptable applications

The combination of stamping & integrated tapping finds applications in numerous industrial sectors:

- Building and construction: cladding brackets, framework supports, wall fixings.

- Automotive and transport: structural parts, mechanical supports, component fixings.

- Furniture and fittings: assembly brackets, shelf supports, reinforcements.

- Electronics: metal chassis and housings with tapped fixing points.

- Medical and food: chip-free stainless steel parts, easy to clean.

In a classic production setup, for example, a manufacturer of M8 tapped metal brackets, integrating tapping into the stamping process often allows for:

- eliminating transport between workshops,

- halving delivery times,

- and strengthening the mechanical quality of the threads thanks to the phenomenon of strain hardening.

Superior mechanical quality

Flow tapping improves thread strength through cold metal deformation. The resulting threads exhibit better tightening resistance, withstand screwing-unscrewing cycles more effectively, and tolerate vibrating environments.

Another advantage: this process is performed without material removal, which makes manufacturing cleaner and safer. The process thus perfectly meets the cleanliness requirements of sensitive sectors such as medical or food processing.

Why choose KUCHLY

Since 1956, KUCHLY has supported manufacturers in the design and production of custom metal parts. Our in-house design office develops progressive dies integrating all deformation and tapping stages.

Each project undergoes a technical feasibility analysis, validated 3D design, and rigorous quality control.

Our presses, equipped with servo systems, monitor tapping torque in real-time to ensure consistent quality. Taps are monitored within a preventive maintenance plan to prevent any deviation due to wear. The pre-drilling diameter is precisely calculated according to the material and sheet thickness: neither too small (risk of breakage) nor too large (weakened thread).

This rigor allows KUCHLY to ensure repeatable quality, even at high production rates.

Our expertise makes the difference

With over 70 years of experience, KUCHLY anticipates the most common errors in the design of tooling combining stamping and tapping:

- Optimized pre-drilling: diameter adjusted according to the material to ensure thread strength.

- Suitable metal selection: selection of steels and stainless steels compatible with cold deformation.

- Tap wear control: preventive maintenance and real-time servo control for constant torque.

- Integrated manufacturing: stamping and tapping performed in the same tooling, ensuring precision and perfect coaxiality.

Free feasibility study

Do you want to know if your part can be stamped and tapped in a single operation?

Our design office will provide you with a feasibility analysis within 48 hours, including an estimate of tooling costs and production lead time.

Contact us to discuss your project and discover how KUCHLY can help you reduce your production costs through stamping with integrated tapping.

FAQ: All about integrated stamping and tapping

What production volumes justify integrated tapping?

The profitability of an integrated stamping with tapping process depends on many factors: part complexity, material type, required tolerances, or production rate.

Generally, this solution becomes particularly attractive as soon as production volumes are regular or significant, with economies of scale allowing for rapid amortization of the combined tooling.

What materials are compatible with flow tapping?

Most steels, stainless steels, and non-ferrous metals can be flow tapped: mild steel, HSLA, galvanized, aluminum, brass, copper, food-grade stainless steel. KUCHLY adjusts lubrication and speed parameters according to each metal.

Why choose flow tapping over conventional tapping?

Because it generates no chips, improves thread strength through strain hardening, and ensures a cleaner process. It is the ideal solution for mechanical parts under stress or intended for demanding environments.