Sheet metal stamping is a manufacturing process that uses a die to form metal parts from folded sheets. It enables the production of parts of various shapes and sizes, with high dimensional accuracy.

It is an ideal technique for the production of lightweight metal parts, as it optimizes production costs, enables complex shapes, ensures a very low defect rate, and high productivity. Stamping is also capable of producing parts from various materials and alloys, such as steel, stainless steel, aluminum, copper, brass, etc.

Advantages of sheet metal stamping for the production of lightweight metal parts

Sheet metal stamping is an economical process for the production of lightweight metal parts due to its low raw material consumption and its ability to reuse tools. This reduces production costs by minimizing material waste and increasing the efficiency of the tools used. By employing effective stamping techniques, companies can produce quality parts at an affordable cost, thereby offering competitive advantages in the market.

Stamped parts of various dimensions and shapes

Presses can produce sheet metal parts of different sizes and thicknesses through stamping, with minimum and maximum limits depending on the characteristics of the press used. Generally, the minimum length of a part can be around 5 mm to 1 cm, while the maximum length can be greater. Width and height can vary similarly. Minimum thicknesses can be in the order of a few tenths of a millimeter, while maximum thicknesses depend on the material used and can reach several tens of millimeters.

Examples of parts produced through stamping include

High dimensional accuracy

Sheet metal stamping is a process that offers high dimensional accuracy, allowing for the production of lightweight metal parts with the exact required dimensions. This precision is achieved through the use of tooling such as dies, blanks, blank holders, and punches, which are used to form the sheet metal according to precise specifications: thicknesses, dimensions, shape, etc. Tools are regularly checked and adjusted to ensure consistent accuracy.

This high dimensional accuracy is crucial for many application sectors, such as aeronautics, automotive, electronic equipment, and medical equipment, where parts must comply with strict specifications to ensure their correct functioning and safety.

High sheet metal deformation capacity

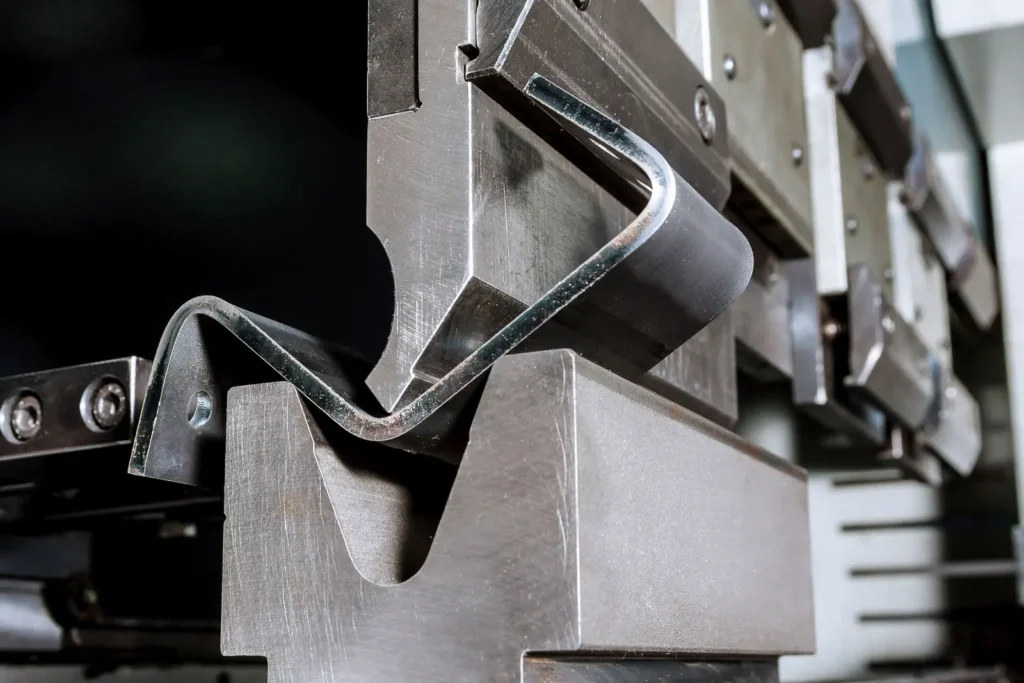

Sheet metal stamping offers a high deformation capacity, allowing for the production of complex shapes that cannot be produced by other manufacturing methods. Presses can subject the sheet metal to significant stresses, enabling the creation of curved shapes, rolled edges, oblong holes, bosses, etc.

Low defect rate for a high production pace

Sheet metal stamping offers a low defect rate due to high dimensional accuracy and the ability to control manufacturing tolerances. Modern presses are often equipped with quality control systems that measure the dimensions of produced parts in real-time, thereby reducing manufacturing errors.

Furthermore, dimensional accuracy can be maintained through the repeatability of stamping operations. By using precise stamping tools and dies designed to produce quality parts, the defect rate can be kept very low, ensuring consistent product quality for manufactured parts.

Moreover, modern presses can produce parts at a high pace, with production rates reaching several hundred parts per hour, or even more, depending on the conditions. The use of high-quality materials, such as stainless steel, can increase production speed and part quality.

Careful control of manufacturing tolerances, along with high dimensional accuracy, ensures that produced parts meet their specifications, with few or no defects, which is a significant advantage for industrial applications requiring reliable and precise stamped parts.

The different phases of sheet metal stamping

We will identify the main stages of the sheet metal stamping process:

- The first phase of sheet metal stamping is sheet metal preparation.

This includes blanking, sheet metal cutting, and cleaning the sheet metal so that it is ready for use. - The second phase involves placing the sheet metal into the die.

This entails positioning the sheet metal in the stamping press die, aligning the edges, and securing the sheet metal in place so that it is ready to be stamped. - The third phase is the stamping itself.

During this stage, the die and punch are used to form the sheet metal using high pressure. The part’s shape is achieved by pressing the sheet metal between the two tools. - The final phase is the finishing of the stamped part.

This includes steps such as deburring, polishing, cleaning, metal processing, and quality control to ensure that the part meets the required specifications.

Kuchly possesses genuine expertise in finishing stamped parts, particularly through collar forming, tapping, and tapping.

➡️ Collar forming is a process that involves creating a rim around a hole, with or without strain hardening. This collar forming process allows for the production of shapes by subjecting the sheet metal to additional deformation in specific areas.

➡️ Tapping is a process of threading holes in metal materials to allow for the assembly of parts with bolts and nuts. Tapping can be performed manually or with specialized machines.

➡️ Strain hardening is a technique for surface hardening a metal part by subjecting it to controlled deformation, such as hammering or cold forming. Strain hardening increases the tensile strength of the metal part and can be used for specific applications requiring increased resistance.