Our KUCHLY stamping plant in REDING is building an entire complex to house an eco-responsible biomass heating system in our future factory.

A boiler room entirely dedicated to green energy

In our new construction project, we were absolutely committed to reducing the carbon footprint for our new factory to ensure long-term sustainability. We aim to be exemplary and inspire others. We have dedicated over 10% of our building investment to a system for heating our new production facility.

This type of heating requires a heavier infrastructure, both in terms of structure and machine installation. The advantage is that it is eco-responsible and allows combustion fumes to be concentrated in a single chimney, thus filtering the air through a particulate filter. Given the installation cost, it was immediately sized to allow us to benefit from it for future expansions.

Lower carbon footprint in a circular economy

To minimize our carbon footprint, the company decided to use its own wood waste, have it shredded, and use it to heat our factory. Indeed, all the steel we stamp is delivered packaged on beech or fir rafters. We wanted to make the best use of this waste without additional transport and thus without CO2 emissions. Instead of treating them as bulky waste, we valorize them by heating our factory.

We see no benefit in purchasing gas that comes from tens of thousands of kilometers away when we have the opportunity to be completely independent of fossil fuels (gas and oil). To achieve this, we are currently erecting the firewalls for our future boiler room and our wood silo. To achieve good efficiency, we have also reinforced the insulation of the entire 2800m² hall to control our energy needs.

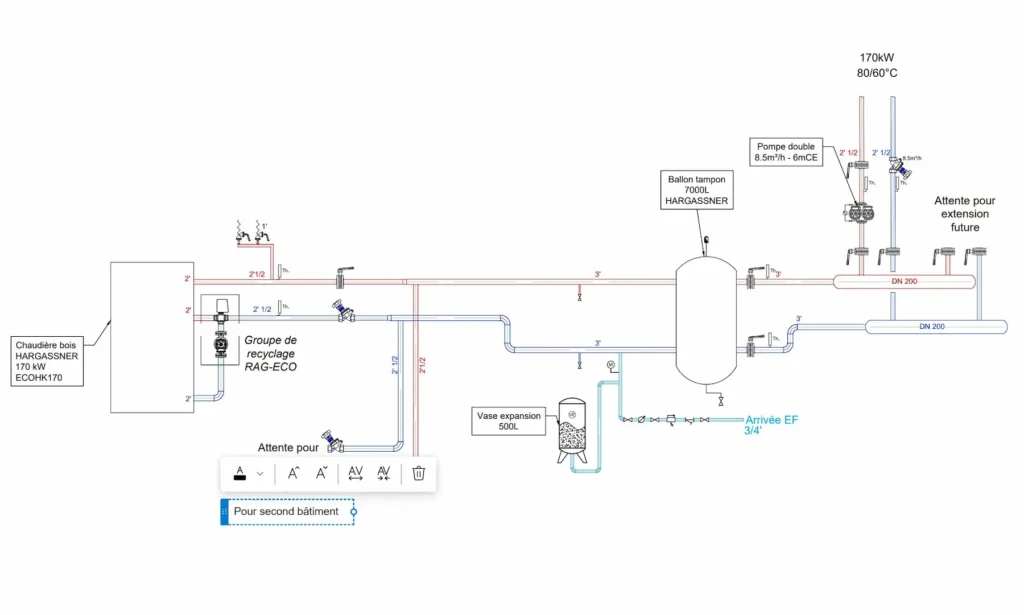

How a Biomass Boiler Works

This boiler operates on the same principle as a pellet or wood boiler. It is much more powerful and can convert wood and agricultural waste into heat. The continuous flame heats a buffer tank of water. Through water/air exchangers, we can heat the entire factory. Thanks to this installation, we valorize our wood waste and reduce our heating bills by 75%.

Climate seeks committed leaders

More information on the BPI France website.