For this new product, the initial tests were conducted by our client. This was to first validate the functionality of the stamped part designed to connect two square tubes positioned at 90° one above the other.

Definition of Requirements and Sizing of the Final Part

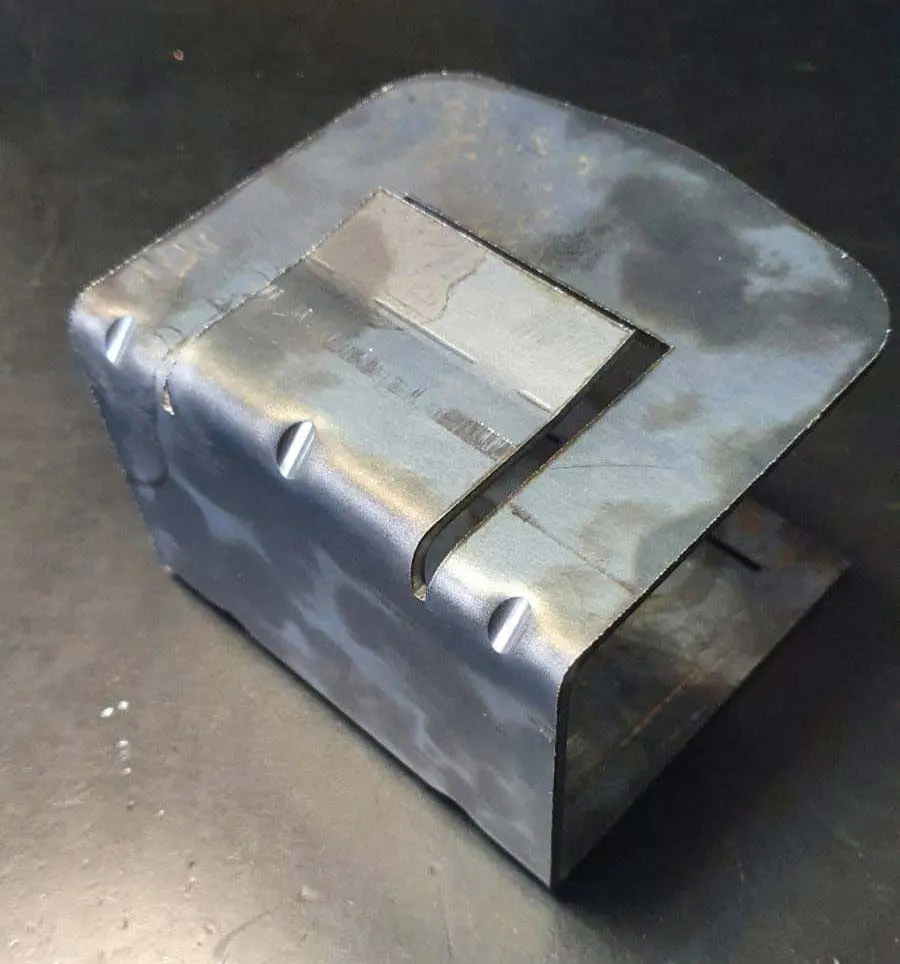

During the design of the part, cuts were made in the 4 mm sheet metal to facilitate easier bending. By performing equivalent section calculations, we observed that the cuts significantly weaken the sheet metal section, by almost 50%.

By performing the calculation, we determined, for the long length of 120, a section of 120x4mm = 480 mm² minus the 50×4=200mm² cut, which yields a useful section of 280 mm². Equivalently, this would result in a thickness of 2.33mm. To ensure the mechanical strength of the assembly, we opted for a 3mm sheet metal, while incorporating ribs in the 90° bend corners to stiffen them.

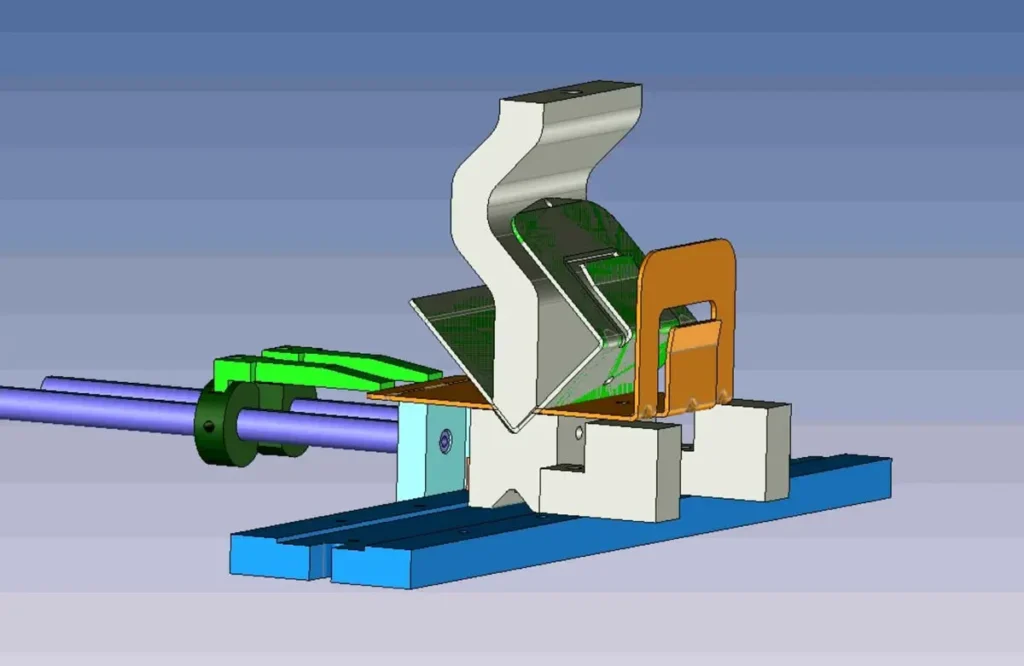

Manufacturing of Punches and Dies

To conduct tests and validate the integrity of the container connections on a 3mm production batch, we manufactured bending elements with the necessary ribs for testing, which are partially reusable for series production. These tests should corroborate our calculations and enable us to produce the series cutting and bending tooling.

For production, we plan to perform the cutting and various bends in a single stroke. The tab and its recessed contour will be bent simultaneously using a roller system. Subsequently, we intend to re-bend the opposite fold to complete the part. This tooling is designed in 3D, and we await your feedback on the thickness test to proceed with manufacturing.