A new client required a system to facilitate the assembly of their metal structure. To achieve this, we produced a set of small sheet metal cutting and bending tools to create shaped parts, thereby avoiding the need to drill and screw the elements together.

Prototyping of fastening clips for solar panels

Initially, in collaboration with our client, we defined their fastening requirements. For this, we established a theoretical geometry and its operating environment, which allowed us to define physical and mechanical characteristics such as the sheet metal section, the material grade, and the surface treatment required for its protection. Following this, we agreed to launch the first prototype parts.

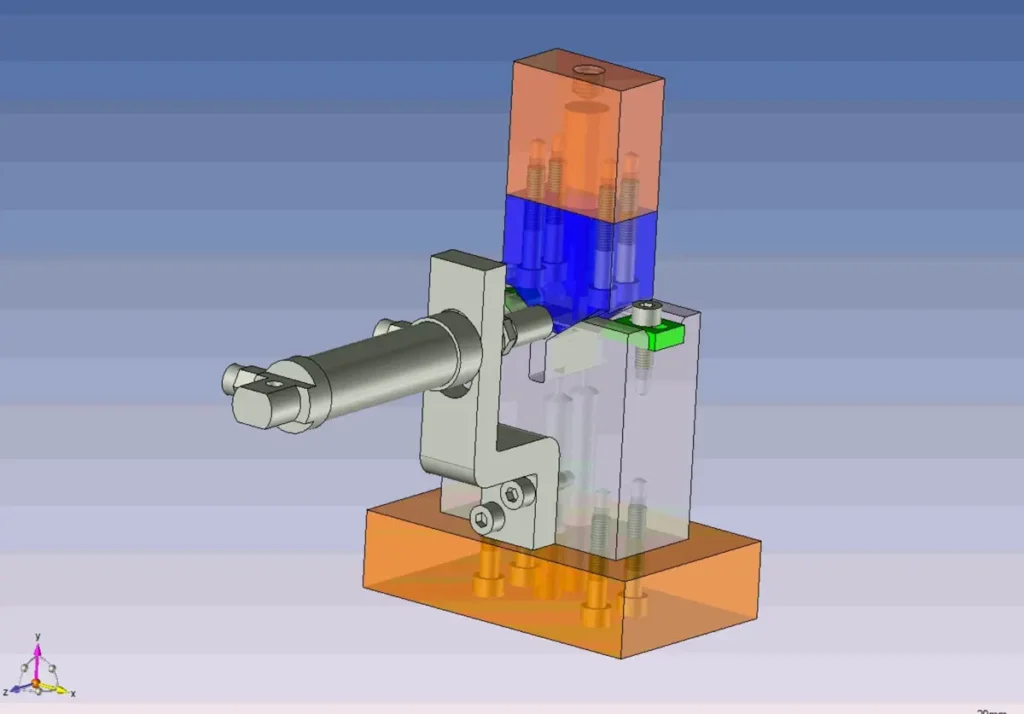

Initially, we produced parts using laser cutting and simultaneously carried out the 3D design of a forming tool. Once the study was completed, we proceeded to Computer-Aided Manufacturing (CAM) to produce the various elements of the

Cutting parts by punching

We developed a punching and cutting tool. For production runs, we will use hardenable C75 S steel with a high carbon content, in the form of slit strip. To ensure mechanical strength and the desired spring effect, the parts will be finished with oil hardening and a protective zinc coating against rust.

For the development of the bending tool, we cut several part samples to determine the correct blank size based on the reaction of C75 S steel during bending operations. For this, we created a cutting tool with an intermediate cut. This technique allows for adjusting the part size with the electronic feed pitch.

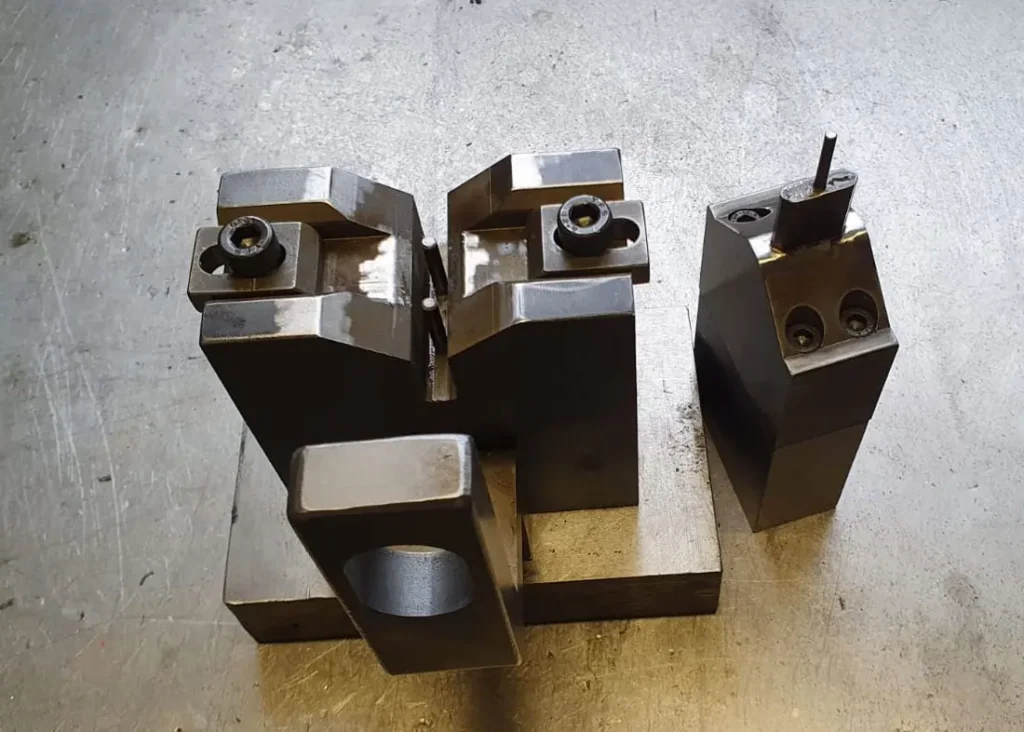

Bending tool for secondary operations

Given the client’s needs for each order, we opted to create forming tools for secondary operations, significantly reducing tooling costs. Once the Initial Samples (IS) were validated by our client, we hardened all bending elements and proceeded with the first production run of this new product.

Discover our partner Ecosun Innovations.