To meet a client’s need for flexible stamped parts and to reduce their transport-related carbon footprint, we have developed a new stamping tool for metal frame collars.

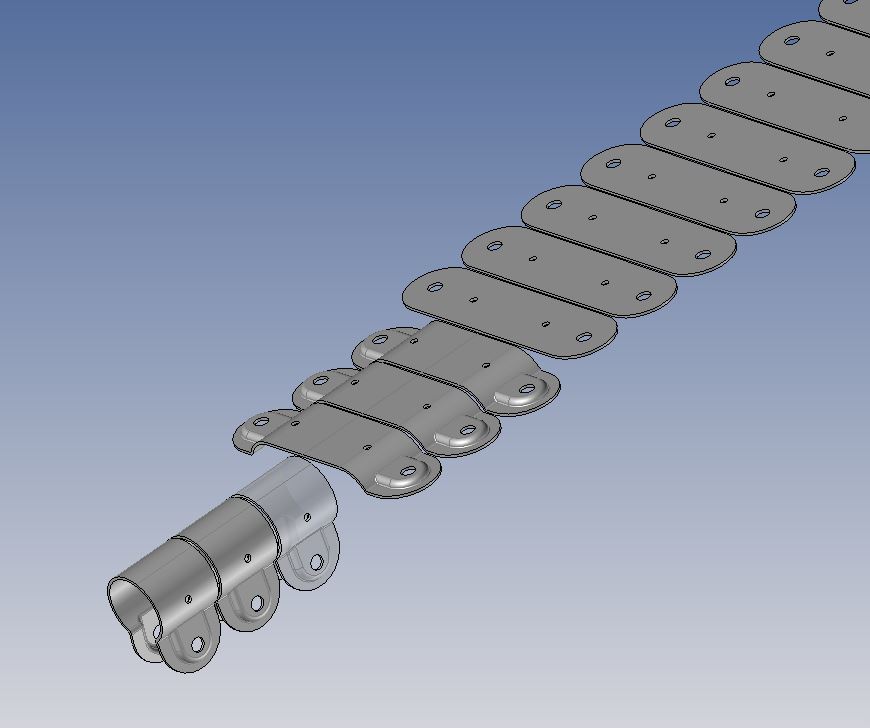

3D Modeling of the Stamped Collar

We begin by 3D modeling the finished stamped and bent part, based on the client’s plan and/or imported 3D models.

This first step allows us to easily visualize the different cutting or stamping stages of the part. It is at this point that we may need to modify certain shapes or intermediate stages to ensure they are feasible.

Once the shape and dimensions are set, we can create the parts representing the preceding stages, then we perform their “strip layout“, which subsequently allows us to represent the strip with the stamping and cutting stages.

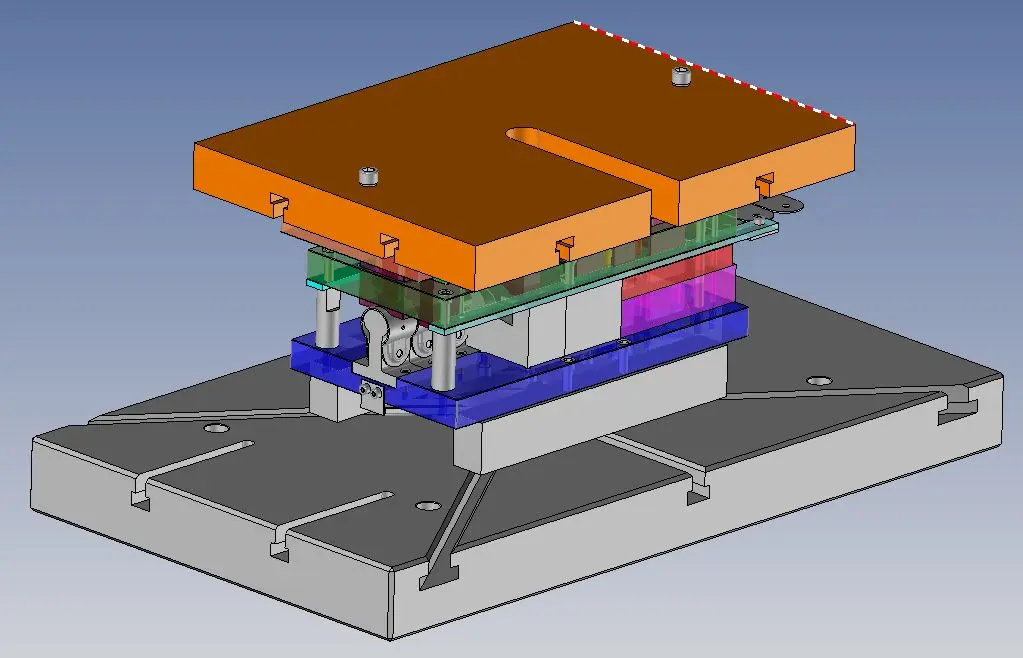

Design of the Progressive Die for Stamped Collar Production

After laying out the stamped parts on the strip and defining the pitch, we then need to dimension the overall tool. Once this is done, the bulk of the work remains. The positioning of the punches and the cutting and stamping forms along the progressive die is extremely important. It must be carefully considered to optimize the tool’s size, operation, and resistance.

The shapes of the internal parts and the various plates must, of course, be achievable with CAD/CAM. Having our own integrated in-house tooling department allows us to facilitate communication and responsiveness in choosing solutions to implement and to optimize the stamping tool’s design.

Manufacturing of the Progressive Die for Collar Stamping

We start with raw drawn steel bars, which we cut to the correct length. They are then ground to achieve the desired height dimension, flatness, and parallelism necessary for tooling production. The internal shapes and external volume of the various plates, as well as the cutting and stamping elements, are produced by milling and EDM using computer-aided manufacturing.

Successive hardening and tempering operations, under controlled conditions, are also performed in-house. The assembly of the complete and precise tool sometimes requires grinding or shimming of certain forms; this is known as tool adjustment or fine-tuning.

Inspection of Stamped Parts

The first stamped parts produced by the tool are thoroughly inspected. Surface finishes, burrs, stampings, and critical dimensions are carefully checked.

Once the tooling operates in normal production mode for the first time, we generally prepare an inspection sheet that is attached to the initial part samples sent to the client. The client can then finally validate the tool if the part’s dimensions are satisfactory.